Outdoor sports fabric: Usually made of nylon, polyester and other synthetic fabrics after processing: all kinds of water craft, calendering, dry and wet coatings, composites, such as film, with a waterproof, breathable, breathable, warm, water pressure resistance, anti-UV functional fabrics. How to achieve these functions?

Feature is the multi-channel technology to achieve post-processing means textile fabric has the product performance, particularly after the processing involved links, how to do these outdoor fabrics, first from the source, the source is weaving and dyeing factory.

1, textile

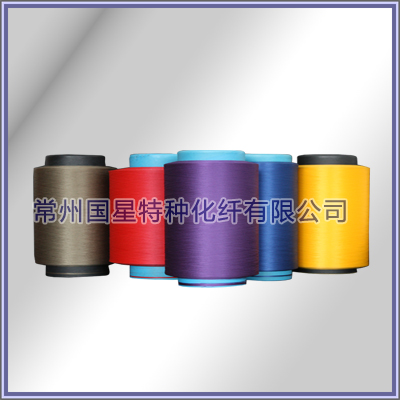

(1) Yarn: Yarn quality fabric quality is good or bad decisions, good or bad decision the fabric tear strength quality. (Chemical Fabrics Yarn represented by D represents denier, used for representing the fineness of chemical fiber and natural silk internationally; Tear: passed the test, the better yarn strength, abrasion wear better, in wild better protection of human action).

(2) Textiles: yarn woven fabric in textile machinery process and adjust the machine, reducing fabric rungs, broken through the weft, holes, and other defects deduction road conditions.

2, printing and dyeing

Dyeing dyeing color must be within the acceptable range, and can not have the yin and yang color, fabric quality qualified, the other is talking about important physical performance test:

(1), touch: requires soft, outdoor sports fabric feels have some more rigid, the development of new products and improve the feel, but outdoor recreation to be softer than some outdoor sports fabrics.

(2), skew: American standard test criteria AstmD3882 dyed fabric requirements are effective width of 3%, plaid and prints requirements are effective width of 2% for qualified products. (Skew if more than the US standard range easily lead to distortion after distortion clothes washed, checked cloth printing Burg-shaped asymmetrical, unsightly).

(3), density: American Standard Testing AstmD3775 requirements warp and weft density within �� 3% qualified.

(4), weight: American standard test ASTMD3776, eligibility requirements within �� 3%.

(5), PH value: American standard test AATCC-81 Requirements 4.5-7.5 (weak acidic body, so is weakly acidic range specified for the human body, if alkaline, the skin vulnerable to irritation dryness uncomfortable).

(6), tear strength: American standard test ASTMD1424, according to the specific requirements of different varieties of fabric (tear kilograms KG, lb LB, Newton N expressed its cloth latitude and longitude values to test, tear or bad, affect the clothing resistance Grinding Naichuan).

(7), stretching intensity: American standard test ASTMD5034, according to the specific requirements of different varieties of fabrics (in kilograms KG, lb LB, Newton N expressed its cloth latitude and longitude values to test, stretch strength is good or bad, affect wear clothing wear resistance).

(8), slip joints: American standard test ASTMD434, according to the specific requirements of different varieties of fabrics (MM represented by its test values, seam strength is good or bad, affect the garment seam slippage).

(9) shrinkage: American standard test AATCC-135 requirements latitude and longitude to �� 3%, (shrinkage in excess of 3%, the impact after wearing clothing washed several times the size of deformation).

(10), light fastness: American standard test AATCC-16E requirements: 20 hours irradiation stage particular lamp 4 and 40 hours of irradiation 3 (mainly anti-sunlight, generally dressed in outdoor clothing to prevent sun on skiing, hiking outdoor sports irradiation difficult to change, in case of danger, its striking color of clothing, waiting for rescue convenient).

(11), rubbing fastness: American standard test AATCC-8 requirements: dry mill 4, wet 3. (This requirement fabric color fading).

(12), color fastness to light: American standard test AATCC-107 Requirements: color 4, staining 3. (This requirement through a cotton, nylon, polyester, wool, acrylic, cloth, etc. Acetate test to see discoloration, staining evaluation grade).

(13), machine washable color fastness: American standard test AATCC-61-2A requirements: color 4, staining 3. (This requirement through a cotton, nylon, polyester, wool, acrylic, cloth, etc. Acetate test to see discoloration, staining evaluation grade).

(14), perspiration fastness: American standard test AATCC-15 Requirements: color 4, staining 3. (This requirement through a cotton, nylon, polyester, wool, acrylic, cloth, etc. Acetate test to see discoloration, staining evaluation grade).

Note: AATCC and ASTM testing standards are the United States, JIS Japanese testing standards, GB for the Chinese standard, the international standard for the United States the most common standards, Chinese national standards testing requirements set for the lowest value;

Color fastness: that fabric panel color fastness, up to five, as a minimum, to judge by the color level is American standard gray card.

+86-519-86266888

+86-519-86266888 gxhx888@126.com

gxhx888@126.com