Air Textured Yarn was invented by DuPont of the United States. The principle is to use compressed air as a power to make a series of physical changes such as opening, displacement, entanglement and entanglement of chemical fiber filaments in the nozzle, so as to obtain and Textured yarns with very different structure and properties of the original silk.

It is characterized by many loops of various shapes and sizes distributed on the surface of the yarn, which is similar to the hairiness of staple fiber yarn; the yarn body is a complex mixture of multiple filaments intertwined, twisted and entangled structure.

These characteristics determine that it has the excellent properties of yarn-like and wool-like yarns. The deformed yarn processed has the properties of both filament and staple fiber yarns, with strong hair feel, good hand feeling, and better coverage than staple fiber yarns.

Air deformation principle

Air deformation is mainly achieved by air deformation nozzles. After the water jet is sprayed into the nozzle, it is blown away and blown by the compressed air jet in the nozzle, and then accelerated in the accelerated wire feeding tube. After leaving the nozzle, the individual filaments are basically kept in parallel, and the yarn in the nozzle chamber is turned at 90 �� to generate curved loops of different sizes. Due to overfeeding, a certain length of free silk segments appears. While the slivers are entangled, a network occurs above the bending point, forming the basic structure of the air deformed yarn. According to the different requirements of the product, it can be shaped or cut in other parts of the air deformer, so that the surface of the yarn can produce fluff similar to short fiber yarn.

Depending on the number of strands fed and the overfeed, the processing techniques for air textured yarns are mainly as follows: single-strand parallel yarn; double-strand parallel yarn; double-strand sheath-core yarn.

In the spinning process of chemical fibers, each filament is not a single filament, but a multifilament composed of 15 to 100 fine filaments. If the compressed air is used to blow the filaments loose during the spinning process, and they are rotated and twisted into a network shape, it becomes a network filament. This kind of silk has high strength, no twisting and sizing is needed during weaving, and no desizing treatment is required for dyeing and finishing, so it is also called "sizing-free silk". Wool-like fabrics are particularly good with net yarns.

Chemical fiber yarns that have undergone deformation treatment (such as strong twist, false twist, non-retractable deformation, etc.) after processing and spinning become textured yarns. Such as strong nylon yarn, expanded acrylic yarn and so on.

Air textured yarn is also called ATY, it is a kind of chemical fiber filament. It uses compressed air to deform the chemical fiber filaments and form small loops on the outer ring, and then breaks them to form a number of head ends exposed to the outside, thereby approaching the "yarn" spun by conventional methods using short filaments. At present, polyester, polypropylene, nylon, viscose, vinegar, etc. all have air textured yarns. Air textured yarn can be used to make silk spinning, cotton-like or wool-like fabrics.

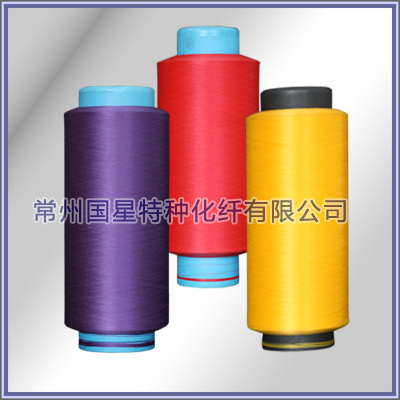

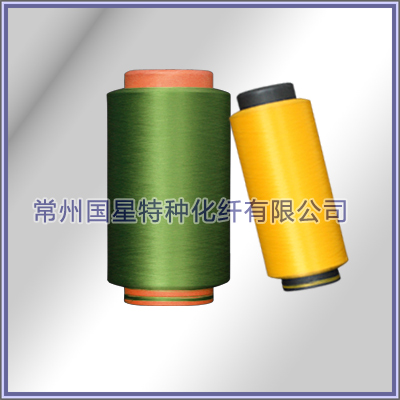

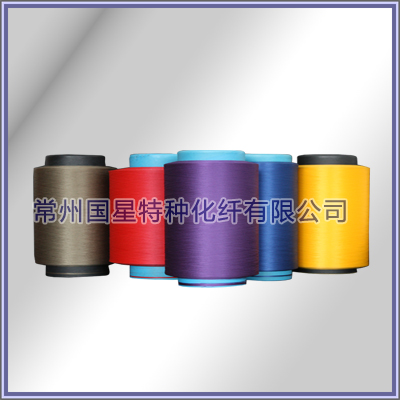

Changzhou Guoxing Special Chemical Fiber Co., Ltd. specializes in the production and operation of polypropylene air change yarn

Polypropylene air-spun yarn, which can be used to make silk spinning, cotton-like or wool-like fabrics. Polypropylene air-changing yarn use: It is widely used in various technical cloths, sofa fabrics, carpet cloths, gauze cloths, decorative cloths, pattern yarns, chenille yarns, craft weaving and other color cloths.

Polypropylene air-transformed yarn Material: PP. Polypropylene air-transformed yarns Advantages: light specific gravity, high strength, corrosion resistance, mildew resistance, good warmth, strong wicking, sweat and moisture absorption, and soft hand. Polypropylene air-transformed yarn has many varieties, complete colors, and quality assurance.

Contact: Mr. Jiang

Mobile: 18915888888

Contact: Mr. Shi

Mobile: 13306121773

Phone: 0519 86266888

Fax: 0519 86268808

Address: No. 3 Zhaiqiao Industrial Concentration Zone, Qianhuang Town, Wujin District, Changzhou City, Jiangsu Province

Chinese official website: http://www.czgxhx.com

English official website: http://www.gxfibre.com

E-mail: gx@gxfibre.com

+86-519-86266888

+86-519-86266888 gxhx888@126.com

gxhx888@126.com