Introduction to the advantages of air changing filament technology and air changing filament

False twist elastic technology, air deformation technology and air network technology are the current three main silk deformation technology, air network silk, also known as air interlocking silk, air interlocking silk, is a way to process yarn with air, network silk is the turbulent air beam sprayed on the silk, so that some of the single fibers produce obvious deflection and other fibers interlocking or network together. So that the silk body is free from sizing and therefore also known as free silk. When two kinds of silk threads with different shrinkage rates, different kinds of silk and different color absorption are networked together, the fabric can obtain various shapes or colors.

False twist elastic yarn is the use of false twist technology, the thermoplastic synthetic fiber to twist, in the twist of the silk body to increase the heat to make the twist state fixed, when the twist is released, the silk body has no twist and presents a curled fluffy state.

The advantages of empty filament are: easy processing; The silk body has no torque, light weight and the silk surface is full, the fabric luster is soft; The silk body has good fluffiness, the fabric is wrinkle-resistant, and the deformation is stable and consistent. Crepe durability is good, fabric elongation is excellent.

According to different processing processes, there are two main forms of air deformed silk.

1. A single kind of wire is processed into a single kind of filament or two parallel super-fed air deformed wires, that is, a single kind of filament is processed, or two kinds of filaments are processed in parallel, the two filaments can be the same kind of raw materials, or different kinds of raw materials, the commonly used feeding wire is FOY wire, it can be a single FOY wire feed deformation nozzle, It can also be a single FOY wire from the creel, two parallel feed nozzle deformation.

2, core wire/skin wire feeding: two kinds of the same or different raw materials, at different superfeeding speeds into the nozzle, forming a core wire/skin wire structure.

3, two kinds of parallel super-feed people processed into air deformation wire, the common deformation wire is FOY wire and FDY wire, or FOY wire and POY wire, two kinds of silk from the creel, parallel super-feed nozzle deformation.

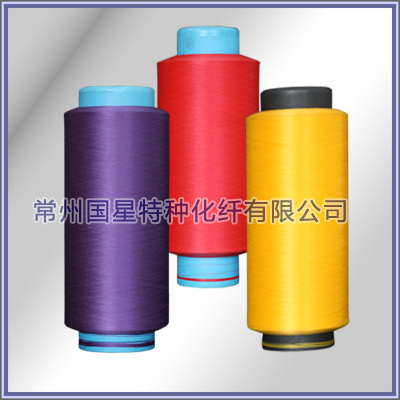

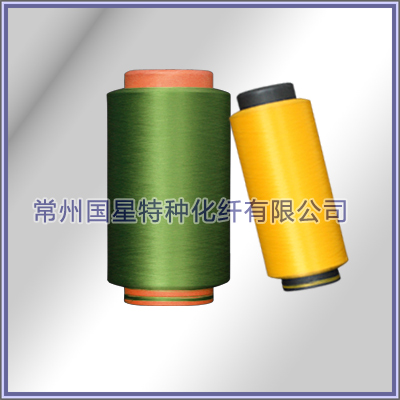

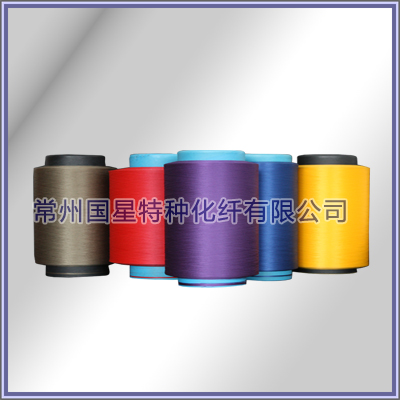

Changzhou Guoxing Special Chemical Fiber Co., Ltd. specializes in the production and operation of polypropylene air conversion yarn

Polypropylene air variable yarn, can be used to make silk, imitation cotton or wool-like fabrics. Polypropylene air silk applications: widely used in a variety of process cloth, sand release, carpet cloth, gauze, decorative cloth, color line, chenille yarn, process weaving and other color cloth, variety, color complete, quality assurance.

Polypropylene air yarn raw material: PP. Polypropylene air silk advantages: light specific gravity, high strength, corrosion resistance, no mold decay, good warmth, strong core absorption, moisture absorption, soft feel. Polypropylene air filament variety, complete color, quality assurance.

Contact: Mr. Jiang

Mobile: 18915888888

Contact: Mr. Shi

Mobile: 13306121773

Tel: 0519 86266888

Fax: 0519 86268808

Add: No.3 Zhaiqiao Industrial Concentration Area, Qianhuang Town, Wujin District, Changzhou City, Jiangsu Province

Chinese website: http://www.czgxhx.com

English website: http://www.gxfibre.com

E-mail: gx@gxfibre.com

+86-519-86266888

+86-519-86266888 gxhx888@126.com

gxhx888@126.com